As I mentioned in

a previous post, we're working on a largish audio/tv cabinet for the

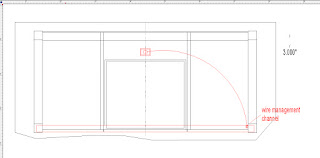

'This Old House' project. It is deceptively simple in appearance with a few little devils in the details, folding and sliding recessed doors being just one of them ...

As on any big project, after the drawings, we mapped out full size layout sticks. These are similar to a carpenter's 'story pole', on which clapboard courses are laid out full size. By transcribing measurements from the drawings full size onto sticks of wood, we can later check our progress against something that is true to life. We put one view per face (front,side,plan), including other details like televisions and audio equipment, that are important to the function of the piece. If we're building something 10', 12 or even 14' long, we will make the long layout view on masking tape and tape it right to the floor where we're going to be working on the piece. Often this is a discovery process of potential flaws in the drawings and a good way to check that things will fit in the spaces in the end ... Different from the drawings, which I usually do, everyone gets to participate in making these sticks and it's a good way to introduce everyone working on it to the complications and subtleties of the finished concept.

Getting under way ... The ply parts and counter mockup are set. The jog in the back of the top cabinet allows the doors to recess into the cabinet, moves the tv forward toward the viewer and creates a 'chimney' to allow heat from the lower area where the components to escape from the cabinet. A final bonus of the stepped out back is that it gives a virtually structureless upper cabinet some rigidity other than the plywood of the back. The back on the lower cabinet is temporarily luan. Click the photos to enlarge them ...

There are a lot of parts to this one ... above, stiles and rails for the doors and end panels

We're veneering the panels of the doors for stability and consistency. We got our extra wide curly maple veneers from

Certainly Wood, one of our two primary wood suppliers. Here, Trevor and Jim are cutting the veneers on the cnc, a job we usually hate to do manually ... There are 16 door and 8 end panel veneers. We made this jig to position the veneer pieces on the cnc and cut them all the same size. Trevor also cut the mdf panels on which Will glued the veneers using the same file so everything is the same size and all parts are exactly square. This was a gold star process that allowed what would have been a time consuming veneering project to move along swiftly.

The finished door panels

The doors and end frames ready for final fit up

The cornice pieces are ready to install and the face frames are on

The doors are glued up and trimmed, ready to be hung on Monday ...

The sides of the cabinets are furred out to receive the side panels which will be mitered to the face frames .... all for now ... we're off til Monday for a mini vacation time